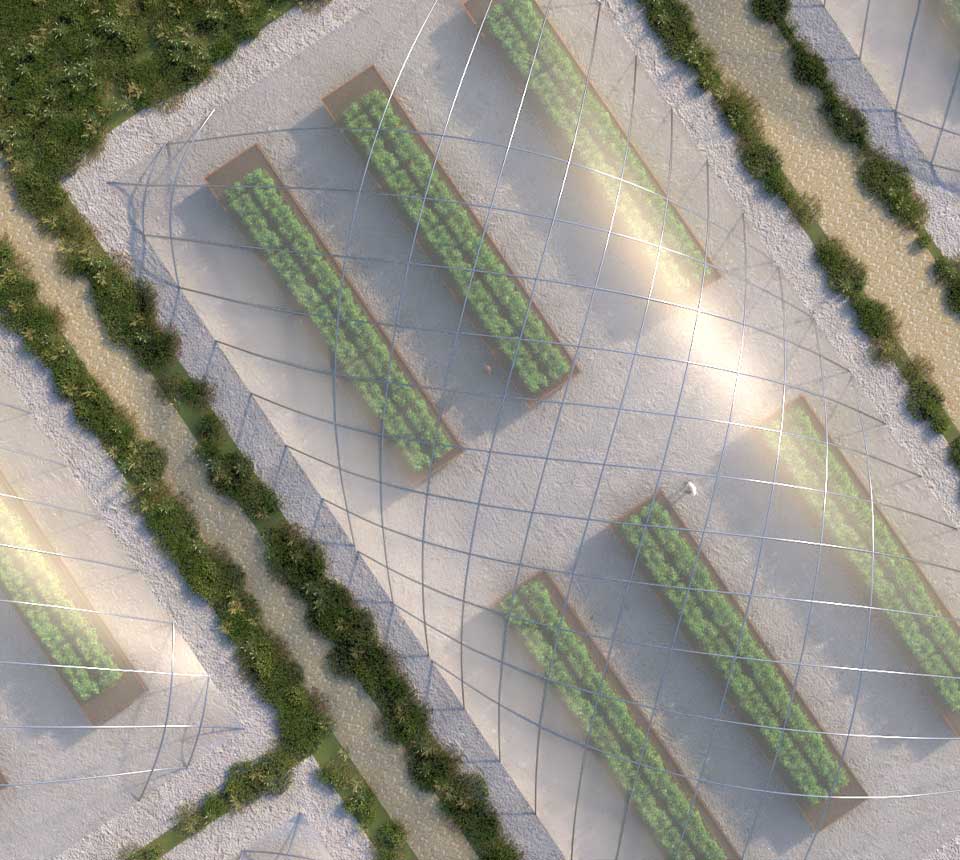

The Brinkworth Road site has the potential to house 56,000 m2 of positively pressured inflatable growing domes.

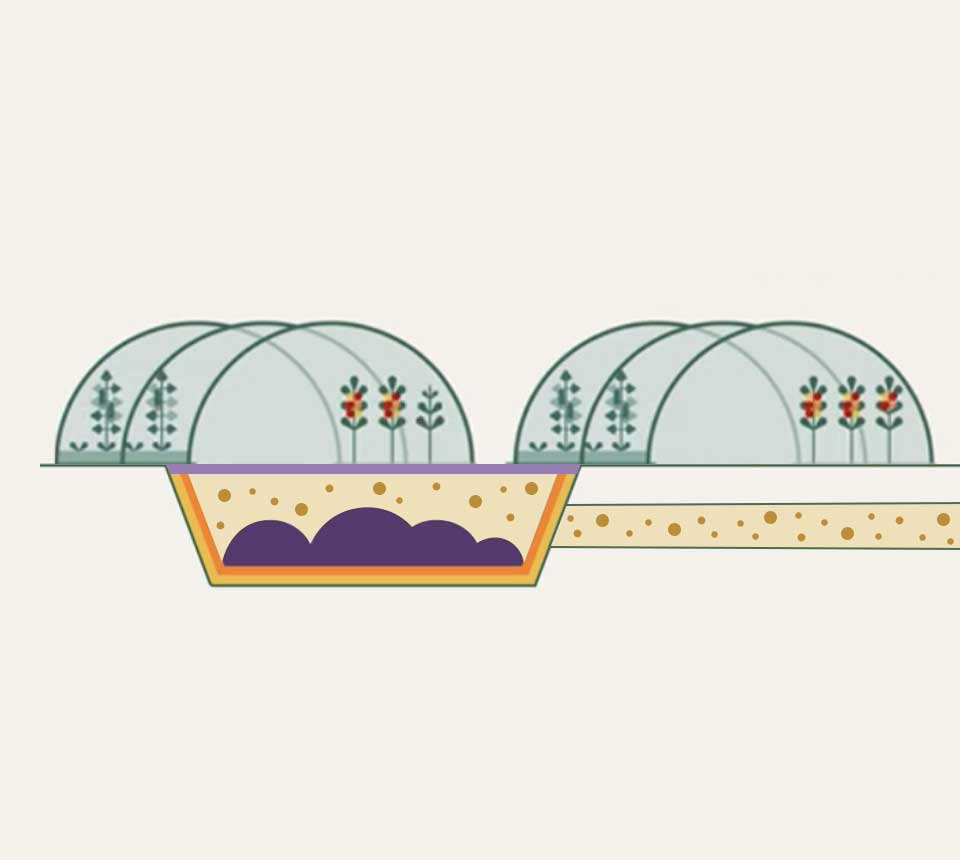

Flexible, positively pressured growing domes are essential for Sustain Wiltshire, because capped landfill sites constantly move due to the production and release of gas, and the natural settling process of the content within its landfill cells.

Our growing domes adjust to the changing lie of the land and prevent the ingress of pests, disease or any external pollutants, including landfill gas.

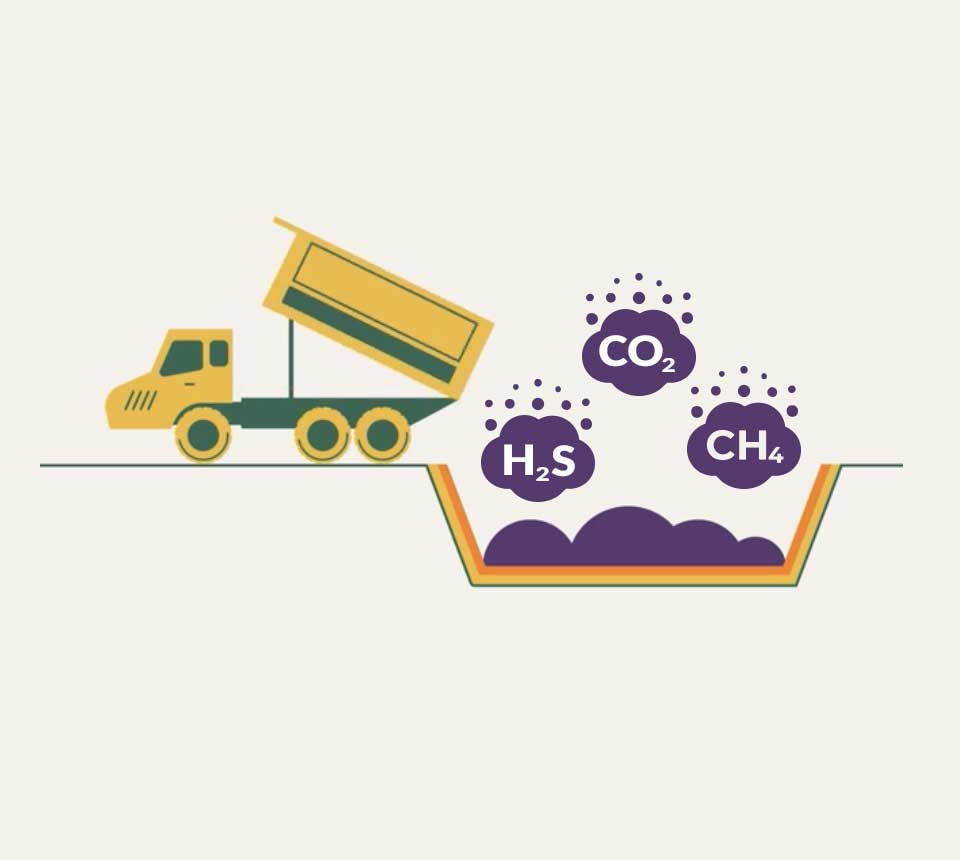

How does energy from landfill methane work?

Landfill gas is primarily composed of Methane (CH4), Carbon Dioxide (CO2) and Hydrogen Sulfide (H2S).

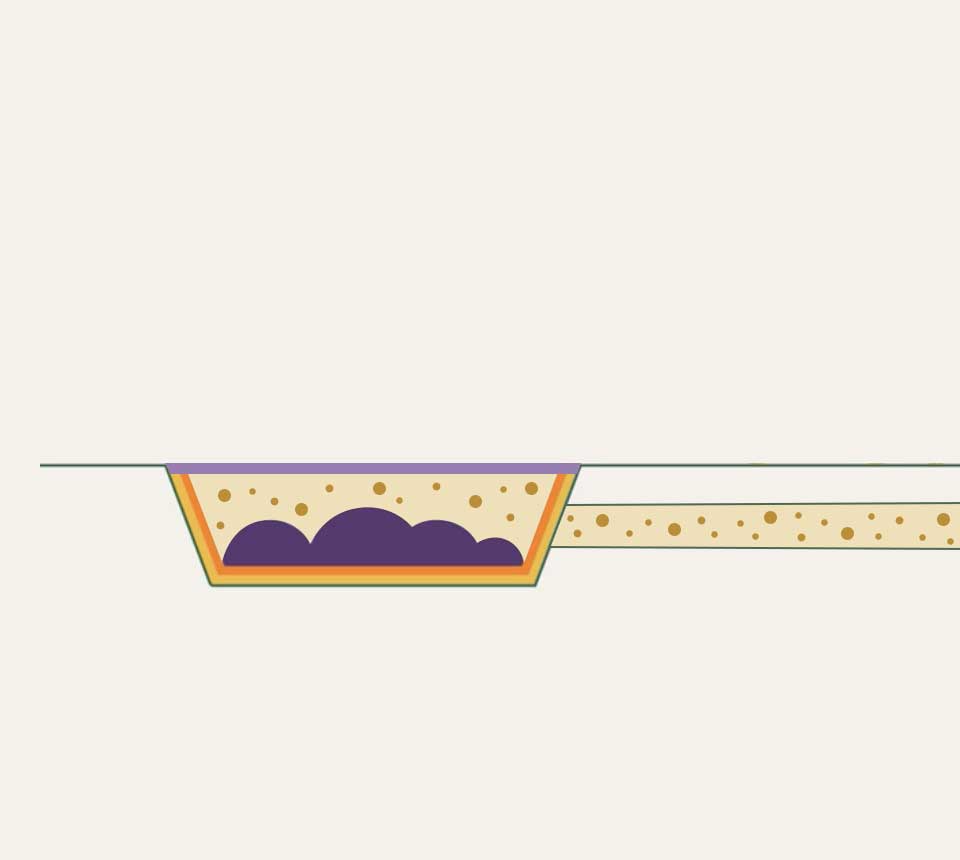

Through a series of wells placed within the landfill, gases from waste decomposition are collected and piped to a central location where it is cleaned by removing the Hydrogen Sulfide.

The collected Methane is used to fuel a Combined Heat and Power Gas Engine. Combined with heat extracted from the landfill site, and power from the on-site energy from waste plant, the positively pressured, inflatable growing domes will be kept at a perfect growing temperature for horticulture throughout the seasons.

Carbon Dioxide will be collected from the engine exhausts, where it will be cleaned and stored for use in the growing domes. The process of photosynthesis will turn the Carbon Dioxide into Oxygen.

How do you know that

positively pressured growing domes will work?

Sustain has received planning permission for a 40m x 20m prototype inflated growing domes, which will be constructed and tested as proof of concept.

Each growing dome is kept rigid through the use of positive pressure and an airlock door that keeps out unwanted insects and pollen. Air pumped in is filtered, regulated, and CO2 increased or reduced to regulate the speed of growth and ripening within the growing dome.

This ground-breaking solution is based on a combination of technologies that have been tried and tested. Pressurised structures, for example, are well proven, making it possible to create environmental conditions inside the growing domes that repel insects and pests so that they cannot affect germination or plant growth inside the growing domes.

CO2 enrichment in growing domes is also well practised, and allows crops to meet their photosynthesis potential. Conventionally, enriching air with CO2 can be achieved by means of the combustion of natural gas or through the use of liquid CO2. Sustain’s Super-Midden solution produces CO2 as a by-product of its methane to energy process.

The use of extra carbon dioxide to increase the yield of growing dome crops is widely used in horticulture. The amount of carbon dioxide in the outside air is typically 350 parts per million. This amount is sufficient for plants to grow, however when placing many plants together in a growing dome, the carbon dioxide levels drop. This is because plants are using carbon dioxide for photosynthesis. By adding CO2 (CO2 enrichment), it is possible to increase the photosynthesis potential of the crops.

Energy from landfill gas is a well proven process which is used internationally. In 2021 energy from landfill gas produced to 3,313 gigawatt hours of electricity in the UK.

Yes. As part of the methane gas to clean energy process, pollutants will be removed from the landfill gas.

Hydrogen sulphate will pass through a biological treatment tower where microbes will break it down.

CO2 will be captured and used in the growing domes to regulate the speed of growth and ripening of produce.

Organic Approach

By adopting pressurised growing domes there will be no need for pesticides, allowing for an organic approach to the production of fruit and vegetables. This is achieved by constantly pumping a mix of filtered CO2 and air into the growing domes, keeping contaminants and disease out.

Airlock doors ensure that no unwanted insects or pollen can enter, helping to ensure biosecurity.

Beehives will be kept in the growing domes to promote pollination. The resulting honey will be available to the local community.

Each 800 sqm growing dome is capable of consuming 58 tonnes of CO2 a year through photosynthesis. Plant leaves pull in carbon dioxide alongside water, using the energy of the sun to convert this into chemical compounds such as sugars that feed plants. Oxygen is produced and released as a by-product of this process, helping to make the Super-Midden process climate friendly.

Mitigation measures will minimise the prospect of light pollution from our growing domes, and will be enhanced by the fact that they will be recessed into the land.

An extensive raised embankment will be built around the site to shield it from Wootton Bassett, the motorway and the railway.

This will be planted with native varieties of trees which will link with the existing woodland to form a green corridor of indigenous woodland, further enhancing the natural environment.

delivered in 2026

Before the first growing domes can become fully operational, the energy from landfill gas plant will need to be built on site. This is a straightforward and well-practiced process.

Once built, it is anticipated that the first trial growing dome will be fully operational within 6 months. This will be operated for 12 months to perfect the design, before construction of the first phase of 20 units begins.

The completion of these will see the first community supplies delivered in 2026.

We anticipate that it will take 10-15 years before all the growing domes are in full operation.